|

Positive displacement (PD) flowmeters are the workhorses of

today’s flowmeter world. They perform many important flow measurements that

many people take for granted. Most notably, they are widely used for water and

gas billing in residential, commercial, and industrial applications. Despite

competition from new-technology meters, positive displacement meters are holding

their own, especially in the oil and gas market.

Flow Research has published a new study, The World

Market for Positive Displacement Flowmeters, 3rd Edition. This is

the first study devoted exclusively to PD meters since our last full positive

displacement study in 2012. Our research, published in December 2021, will

determine how well PD meters are holding their own in today’s competitive

environment.

Flow

Research forecasts that PD revenues and units sold worldwide will stay

relatively steady through 2024. China is expected to show the highest growth due to its

economy, including increased activity in downstream oil and gas. In

general, PD meters are widely used to measure the flow of

hydrocarbon products at custody transfer points both upstream and downstream of

refineries.

How PD meters work

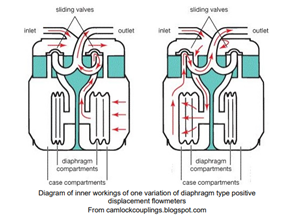

PD flowmeters

operate by repeatedly filling and emptying compartments of known volume with the

liquid or gas from the flowstream. Flowrate is calculated based on the number of

times these compartments are filled and emptied. The main types of PD flowmeters

used for gas applications are diaphragm and rotary. These types of meters differ

according to the way they trap the liquid into compartments with different

shapes.

The

main PD flowmeter types are: The

main PD flowmeter types are:

• Oval gear

• Rotary

• Helical gear

• Nutating disc

• Oscillating piston

• Diaphragm

• Spur gear

Diaphragm meters have several diaphragms that capture the fluid as it passes

through the meter. Differential pressure across the meter causes one diaphragm

to expand and one to contract. A rotating crank mechanism helps produce a smooth

flow of gas through the meter. This mechanism is connected via gearing to the

index, which registers the amount of fluid that passes through the meter.

Diaphragm meters are used for gas applications.

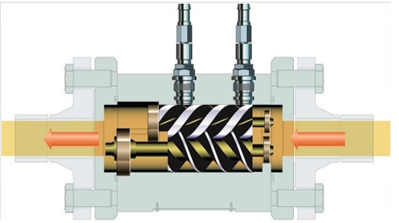

Rotary flowmeters have one or more rotors that are used to trap the fluid. With

each rotation of the rotors, a specific amount of fluid is captured. Flowrate is

proportional to the rotational velocity of the rotors. Rotary meters are used

for gas applications.

Thomas Glover of England invented the first diaphragm meter in 1843. Glover’s

meter was made in response to difficulties with liquid sealed drum meters, which

were created in the early 1800s. This meter had diaphragms of sheepskin and with

sheet metal enclosures. Today diaphragm meters are made from cast aluminum and

have diaphragms of synthetic rubber-on-cloth.

Why the PD

market is still growing

The large,

saturated PD market makes revenue growth challenging. However, at the same time,

the PD market overall benefits from the strength of a large installed base, high

accuracy, and its strength in the utilities market.

Even though

PD meters face stiff competition from new-technology meters in some segments,

they still remain the best solution for certain applications. PD meters excel

where many other flowmeters have difficulties: low flow rates and high viscosity

liquids.

Positive displacement flowmeters remain one of the most widely used types of

flowmeters for measuring the flow of water, gas, and petroleum liquids. They

remain a solid choice for many applications in today’s modern process control

environment.

Large

installed base

One major growth factor for positive displacement flowmeters is the large

installed base of positive displacement flowmeters worldwide. Because they were

introduced more than 100 years before new-technology meters, PD flowmeters have

had much more time to penetrate the markets in Europe, North America, and Asia.

Installed base is a relevant growth factor because often when ordering

flowmeters, especially for replacement purposes, users tend to replace like with

like. The investment in a flowmeter technology is more than just the cost of the

meter itself. It also includes the time and money invested in training people

how to install and use the meter. In addition, some companies stock spare parts

or even spare meters for replacement purposes. As a result, when companies

consider switching from one flowmeter technology to another, there is more than

just the purchase price to consider. We predict that the large installed base of

positive displacement flowmeters worldwide will continue to be a source of

orders for new and replacement meters in the future.

High accuracy a major factor

Accuracy and reliability continue to be the strongest driving forces behind the

flowmeter market -- and positive displacement meters are highly accurate because

they actually separate the fluid into compartments and count the number of times

this is done. There is no need for the inferential method that occurs with

meters that correlate flow with velocity, or use the differential pressure

method to measure flow. PD meters are widely used for billing applications

because they are both accurate and reliable. Both the degree of accuracy and

reliability vary with the manufacturer and the type of PD meter.

Utility applications dominate

While

new-technology flowmeters are making inroads into traditional meters in many

areas and applications, this is less true for positive displacement flowmeters

for gas applications. Close to 80 percent of revenues from PD meters for gas

flow measurement derive from utility applications, where PD meters are highly

entrenched. This includes PD meters for commercial and industrial

applications, where utility companies use them to measure the amount of gas

consumed by restaurants, office buildings, and other establishments. While there

has been a shift from diaphragm to rotary PD meters for these applications,

these applications have seen no strong shift away from PD meters. Turbine meters

are used for high speed flow utility applications, however. While

new-technology flowmeters are making inroads into traditional meters in many

areas and applications, this is less true for positive displacement flowmeters

for gas applications. Close to 80 percent of revenues from PD meters for gas

flow measurement derive from utility applications, where PD meters are highly

entrenched. This includes PD meters for commercial and industrial

applications, where utility companies use them to measure the amount of gas

consumed by restaurants, office buildings, and other establishments. While there

has been a shift from diaphragm to rotary PD meters for these applications,

these applications have seen no strong shift away from PD meters. Turbine meters

are used for high speed flow utility applications, however.

The use of PD diaphragm and rotary meters for gas applications is somewhat like

the use of nutating disc and piston PD meters for utility and billing

applications in the water industry. PD meters, along with single-jet and

multi-jet turbines are still the dominant meter for utility measurement of water

flows, especially in residential and smaller commercial applications. However,

some new-technology flowmeters such as magnetic and Coriolis are beginning to

gain approvals from industry associations for use in utility measurement of

water. It is likely, then, that new-technology meters will eventually be used on

a more widespread basis for utility gas measurement.

Thomas

Glover of England invented the first diaphragm meter in 1843. Glover’s meter

was made in response to difficulties with liquid sealed drum meters, which were

created in the early 1800s. This meter had diaphragms of sheepskin and with

sheet metal enclosures. Today diaphragm meters are made from cast aluminum and

have diaphragms of synthetic rubber-on-cloth.

Articles

About Positive Displacement Flowmeters

The

World Market for Positive Displacement Flowmeters, 2nd Edition

Published in

2012

The

World Market for Positive Displacement Flowmeters

Published in 2002

|